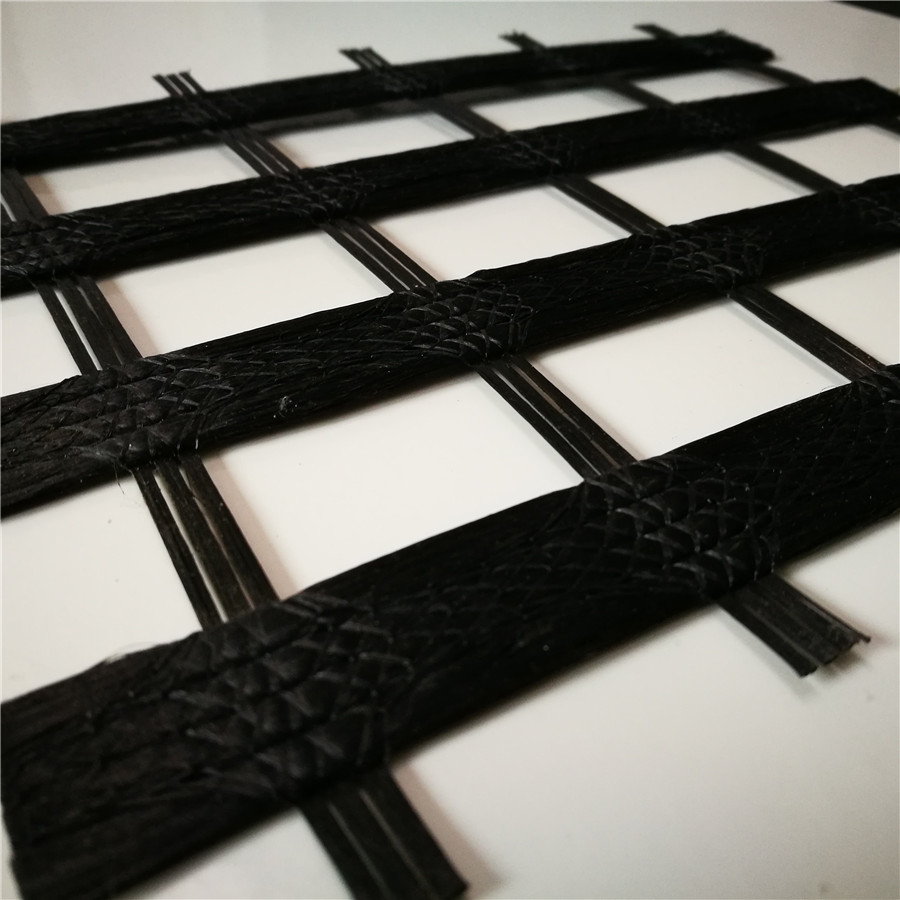

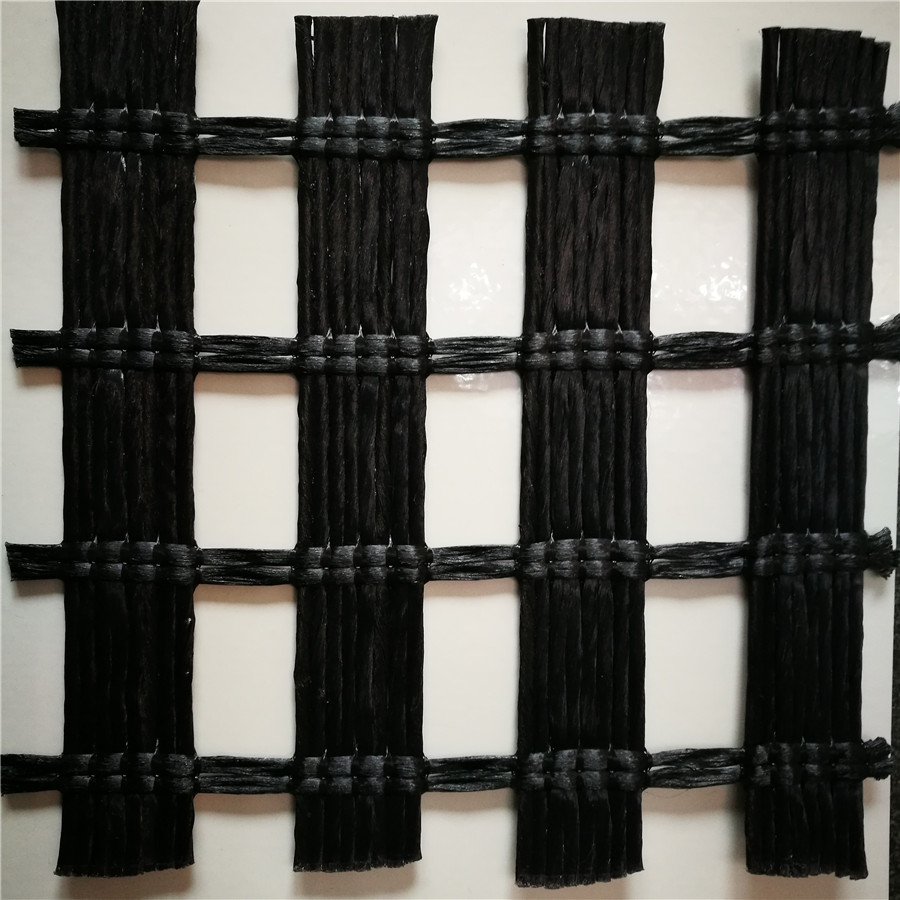

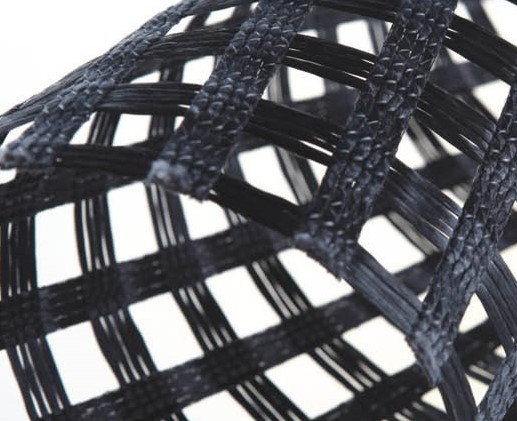

Polyester GeoGrid

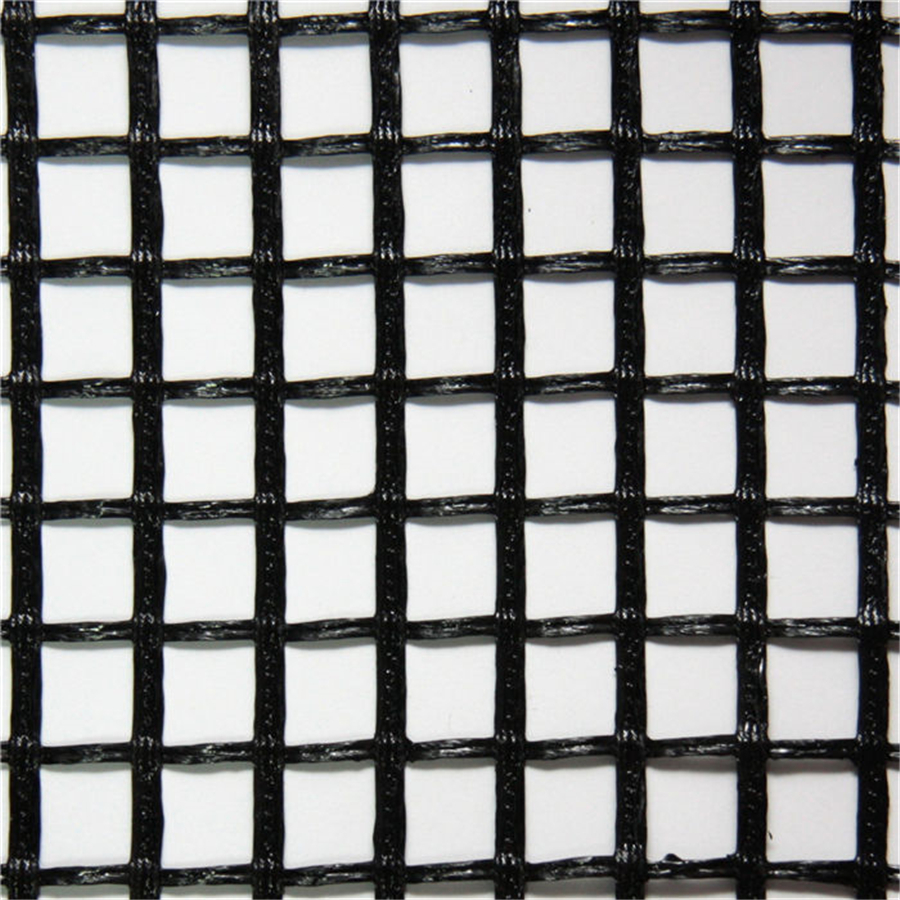

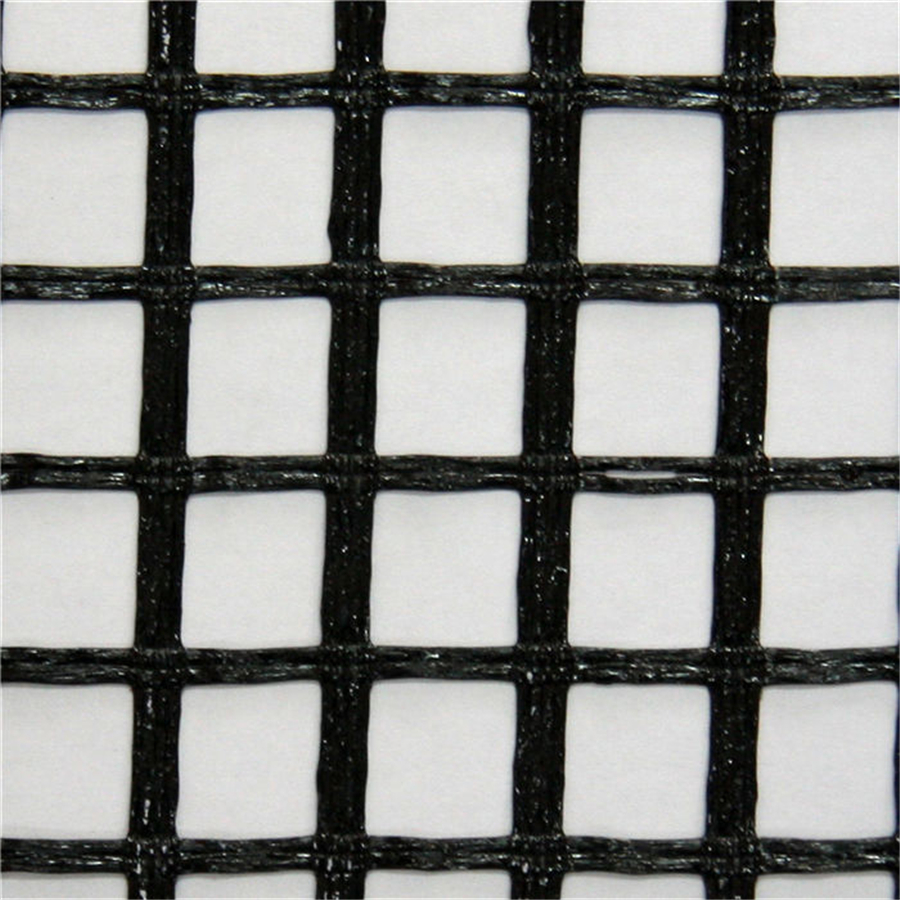

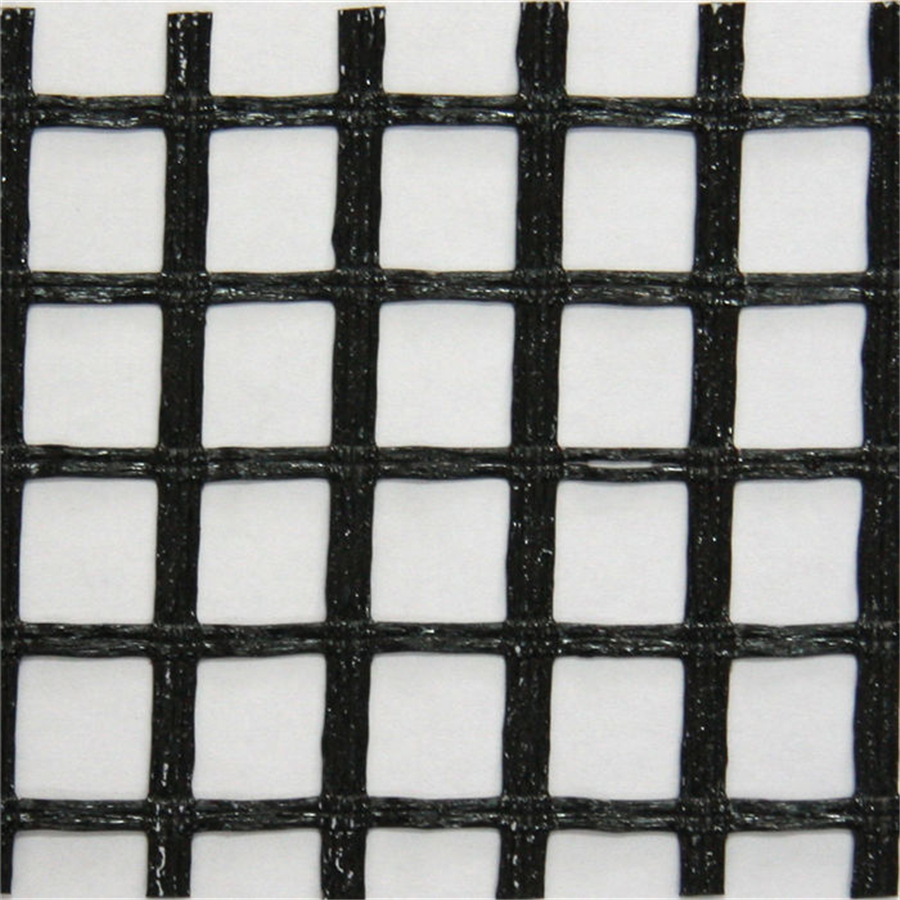

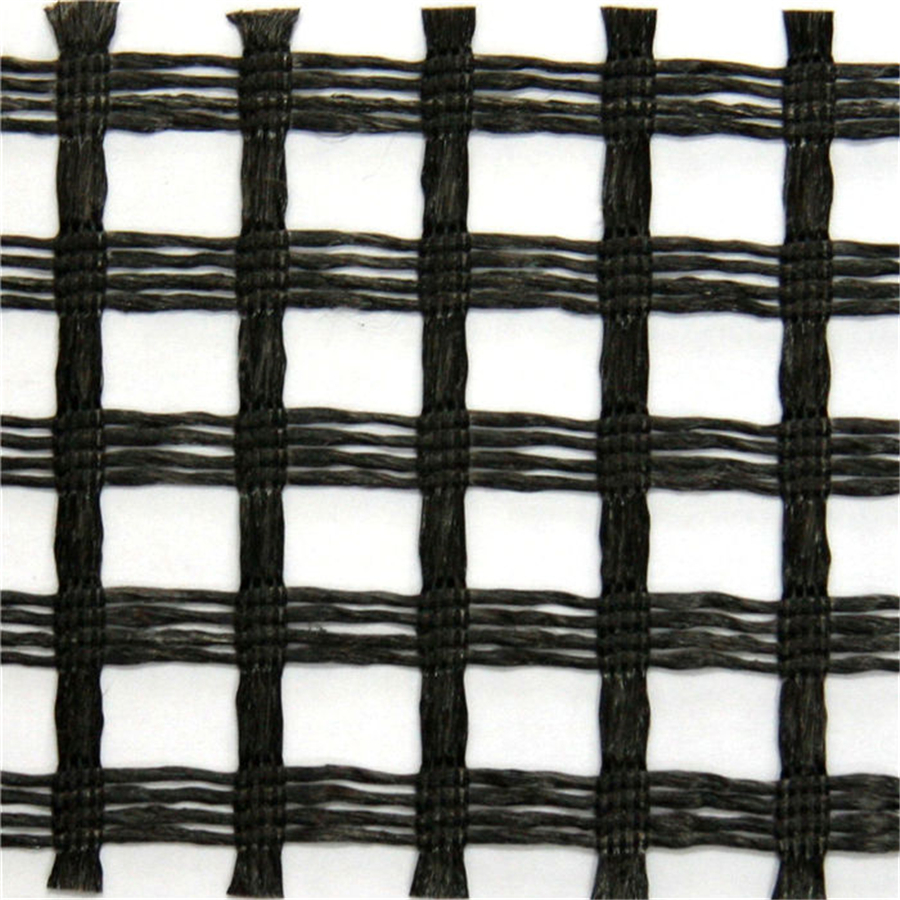

Polyester Geogrid PVC Coated

Product introduction:

The warp knitting polyester geogrid selects industrial high-strength, anti-embrittlement, low shrinkage polyester yarn as raw material, adopts the warp knitting oriented structure, latitude and longitude in the fabric to the yarn to each other without bending state,

Intersection sewn up with high strength fiber filament bundle, forming strong combining site, and through high-quality oil or water based PVC coating processing and form the plane shape of material, fully Play its mechanical properties.

Features:

The warp knitting polyester geogrid has high strength, high modulus, low creep, anti-aging, brittle crack resistance, high tensile strength, tensile strength, with the soil crushed stone binding force strong and

May pre-design many kinds of characteristics.

Application:

1, highway and repair roads, railway, airport, soft subgrade.

2, embankment slope strengthening solid, the Banks of the river.

3, all kinds of solid foundation.

4, road and bridge pavement.

- For Bi-axial type:

Technical data:

Specification | 30/30PET | 50/50PET | 100/100PET | 200/200PET | 300/300PET | 100/30PET | 200/50PET | |

Break elongation | 14% | 14% | 14% | 14% | 14% | 14% | 14% | |

Breaking Strength | MD | 30 | 50 | 100 | 200 | 300 | 100 | 200 |

CMD | 30 | 50 | 100 | 200 | 300 | 30 | 50 | |

Aperture size mm | 25.4×25.4 ~ 50x50 | |||||||

Width m | 2~5.3 | |||||||

- For Uni-axial type:

| Product Properties | |||||||||||

| Physical Properties | Units | TG40/20 | TG60/20 | TG80/30 | TG100/30 | TG120/30 | TG150/30 | TG200/30 | TG250/30 | TG300/30 | Test Method |

| Material | High Tenacity Polyester Yarn Coated With PVC | ||||||||||

| Grid Size - MD (Central to Central) | mm | 25.4 | |||||||||

| Grid Size - CD (Central to Central) | mm | 25.4 | |||||||||

| Mechanical Index Properties | |||||||||||

| Tensile Strength , - MD min | kN/m | 40 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | 300 | ASTM D6637 |

| Tensile Strength , - CD min | kN/m | 20 | 20 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ASTM D6637 |

| Elongation - MD | % | ≦13 | ≦13 | ≦13 | ≦13 | ≦13 | ≦13 | ≦13 | ≦13 | ≦13 | ASTM D6637 |

| Tensile Strength at 2% Strain- MD/CD min | kN/m | 7/3 | 10/3 | 14/5 | 19/5 | 21/5 | 27/5 | 42/5 | 45/5 | 54/5 | ASTM D6637 |

| Tensile Strength at 5% Strain- MD/CD min | kN/m | 16/8 | 25/8 | 34/11 | 42/11 | 50/11 | 63/11 | 83/11 | 105/11 | 125/11 | ASTM D6637 |

| Long-Term Design Properties | |||||||||||

| Creep Reduction Factor, RFCR | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | ASTM D5262 | |

| Installation Damage Reduction Factor, RFID | 1.12 | 1.12 | 1.12 | 1.12 | 1.12 | 1.12 | 1.12 | 1.12 | 1.12 | ||

| Durability Reduction Factor, RFD 1 | 1.16 | 1.16 | 1.16 | 1.16 | 1.16 | 1.16 | 1.16 | 1.16 | 1.16 | ||

| Reduction Factor, RF=RFCRXRFIDXRFD | 1.92 | 1.92 | 1.92 | 1.92 | 1.92 | 1.92 | 1.92 | 1.92 | 1.92 | ||

| LTDS (114 yrs), Tallow 2 | kN/m | 20 | 30 | 40 | 50 | 60 | 75 | 100 | 125 | 150 | |

| Dimensional Characteristics | |||||||||||

| Length | m | 50-100 | |||||||||

| Width | m | 5 | |||||||||